What Is A Capstan Winch? Types, Features, Applications & Safety Precautions In 2023

A capstan winch is a revolving device with a bollard designed to increase the pulling force for hauling big objects. The forestry, mining, construction, demolition, and industrial industries use capstan winches.

They are made and intended to work with take-up trolleys and counterweights for longwall product transfer in mines. On sailing ships, this type of winch is known as a vertical axis.

Utilizing a revolving tool that assists in applying pressure and bringing sails, cables, and ropes up on deck.

Table of Contents

Modern capstan winches can achieve fast speeds, and strong line pulls. Manual, electrical, or hydraulic power can operate these winches.

Whether or not they have an engine, it drives the crankshaft. On sailing vessels, a capstan winch is frequently used to tighten or loosen ropes that can lift or lower sails and other objects.

The capstan winch does not retain the entire length of the rope; instead, it serves as a bridge between the two ends of the rope, in contrast to more contemporary winches that install the rope or cable on a drum.

The capstan is a vertical barrel that turns to deliver stress to the rope; formerly, several men would turn the barrel together using leverage poles.

Features Of Capstan Winch:

- They can be used outside because they are weatherproof.

- They require very little upkeep and are immediately usable.

- Capstans may pull in any direction, unlike a typical winch.

- Rope can exit the drum at any angle, allowing the operator to stand in the most suitable posture.

- Winches with capstans are safer than other winches if they are correctly utilized.

- They can accommodate numerous sizes and varieties of rope.

- The backstop can be configured for slanting uses.

- Their travel speed can be changed to meet the consumer’s needs.

- Portable devices fitted on a durable steel frame for mobility are available

How Does A Capstan Winch Work?

Winches are helpful and occur in several varieties. Capstan winches come in two varieties: electric and manual.

The first type operates manually, while the second uses an electric motor. The manual capstan winch’s operation is the main topic of this essay.

The critical parts of the winch are described, including the

- Reel

- Drive system

- Bearings

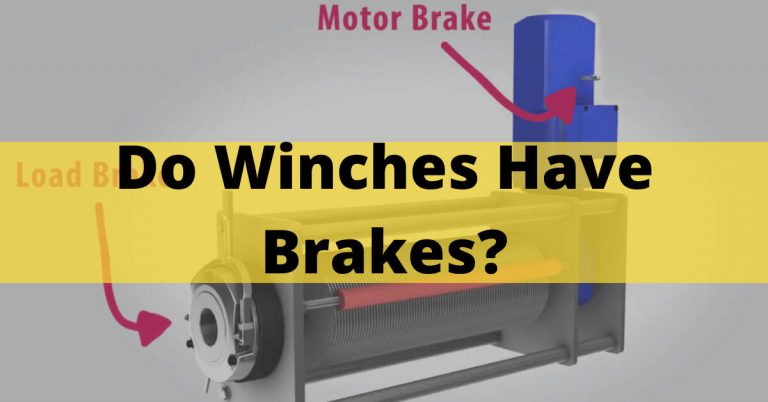

- Brake

- Shaft

- Drive pulley

- Spring clutch

- Gearbox

The method of use is described, and the function of each component is.

Mechanism Of Operation:

An effort must be made to start a capstan winch by pulling on the handle, which turns the reel. The reel’s big attached drum has teeth all around it that mesh with a driving gear fastened to the shaft.

The teeth and driven gear meshing transform the pulling force into the shaft’s rotating motion. To ensure that the driving mechanism stops at the end of the rotation, the shaft’s movement triggers the braking system, which further restricts the shaft’s movement.

The springs that serve as gripping mechanisms also regulate the speed of rotation. They ensure the rotation doesn’t go on for an excessive time.

The lifting weight is transported by a cable that is looped around the reel; it is simple to remove the cable when it is needed.

Different Types Of Capstan Winch:

According to motive power, these are different types of capstan winch:

1. Electric Pulling Capstan Winch:

Personal electrical power equipment is used to power the electric pulling capstan winch. An electric pulling capstan winch safety is adaptable and changeable in the wateriness area to attain multi-position assemblies.

It has other advantages beyond comparison, like the ability to function when a car is in a stall.

2. Small Capstan Winch:

The little capstan winch is lightweight, has a clever appearance, and works effectively.

It can quickly obtain power and save the most time and labor possible.

By selecting a small capstan winch, you can get the most comfort for your money.

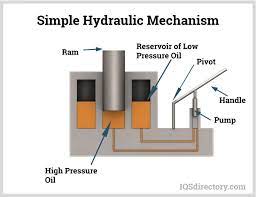

3. Hydraulic Capstan Winch:

The real power of a hydraulic capstan winch can also be fitted without difficulty.

The hydraulic capstan winch finds its driving force between the PTO marine capstan machine and the electric ship capstan machine.

There is no issue with the temperature here.

4. Capstan Rope Winch:

Your productivity and job efficiency will increase if you use a capstan rope winch.

8-foot cable and loop drive chain are part of the complete high safety rope capstan lifting system.

Heat-treated gears and shafts of the capstan rope winch are designed to suit your chain saw effortlessly.

5. Manual Capstan Winch:

Hand motion in vertical and circular planes is typically used as the driving force for manual capstan winches.

Due to the labor shortage, manual mooring capstan winches possess reduced tensile force.

Benefits Of Capstan Winches:

Comparing capstan winches to traditional hoists and derricks reveals various advantages. Among these advantages are:

1. Low Capital Cost:

When compared to other hoists and derricks, installing a capstan winch is inexpensive at first.

They are affordable, have low operating expenses, and offer significant labor cost reductions.

Additional maintenance procedures and specialized safety equipment are not required, further lowering operational expenses.

2. Space-Saving:

Capstan winches require less room than their competitors because of their small form.

They can also be mounted directly into a regular railroad platform and take up very little room.

3. Easy To Operate:

Capstan winches are easy to use because of their streamlined construction.

To handle them, no vast cranes nor specialized operators are required. They can be moved at full speed with ease by a light engine.

4. Multiple Attachments:

Capstan winches are a perfect fit with various attachments such as

- Air Guns

- Cranes

- Lifting booms

- Backfill

- Loading grabs

- Forklifts

- Rock baskets

- Conveyors

The mining and construction sectors both use capstan winches extensively.

5. Design:

They are perfect for distant locations were transporting heavy equipment is challenging because of their straightforward design.

Additionally, capstan winches can be transported on-site without using specialist trucks. A capstan winch is suited for pulling by weak power sources because of its low weight.

Drawback:

Capstan winches have several disadvantages as well, though, which may restrict their application. The requirement to lift the weight at high speeds is the most significant disadvantage.

They must be connected to big, solid engines and pullers. It dramatically raises the price of installing and running the system. The engine must be started with a relatively high starting torque, which adds to engine wear and tears and raises noise levels.

Application Of Capstan Winches:

Capstan winches are highly useful and have a variety of uses. A few of their uses include:

1. Underground Mines & Tunnels:

Capstan winches are not only a great way to load materials from deep mine shafts but may also be employed to bring workers from underground workings to the surface in an emergency.

The machines may rescue miners from deep tunnels if a fire or gas explosion occurs.

2. Tractor Operations:

When driving a plow up steep slopes, tractor operators may prefer to use capstan winches rather than hydraulics.

3. Harbor & Harbor Berths:

For unloading ships at docks and harbors, capstan winches are frequently used. Capstan winches can be used instead of complicated hoisting systems, which reduces the risk of injury to employees or cargo.

4. Hydraulic Lift Systems:

While heavy lift cranes and the lack of chain sprockets are some benefits of hydraulic systems over other lifting techniques, there are also disadvantages.

Complex valves, pumps, and cylinders used in hydraulic systems necessitate routine comprehensive repair, which raises the cost of operation.

Capstan winches are more straightforward to use and have fewer moving parts. They are ideal for various applications because they don’t need additional space for upkeep.

Safety Precautions

If sufficient safety measures are not performed, winches can be rather dangerous.

So go through the safety instructions before starting to assemble your winch.

- When working with winches, always wear gloves and avoid letting your fingers touch the rope with the gloves on.

- Keep kids away from the area around winches.

- As much as you can, use winches on flat areas.

- Always wrap at least five complete rounds of rope around the winch drum.

- When attempting to free the ropes from the drum, maintain your hand flat against the surface and avoid letting your fingers tuck into the strings.

Capstan Vs. Winch:

1. Capstan:

An apparatus for applying force to ropes, cables, etc., is vertical and cylindrical and rotates on a spindle. A drumhead with sockets for levers to turn it is often placed on top of it.

A vertically cleated drum or cylinder with sockets for bars or levers on top, rotating on an upright spindle. It is frequently used on ships to move or raise heavy objects or generate significant force by pulling on a rope or cable that passes around the drum.

It is either powered by steam or a group of men pressing on the ends of levers fixed in its socket while they circle the capstan. A tape recorder’s mechanism for advancing tape through a spinning spindle.

2. Winch:

- A device made out of a drum on an axle, a friction brake, ratchet and pawl, and a prime mover (often an electric or hydraulic engine), with or without gearing, to provide improved mechanical advantage while tugging on a rope or cord.

- Hoisting device for bringing lines of freight in or out, or for loading or unloading cargo

- The wince (a machine used in dyeing or steeping cloth).

What Is A Portable Capstan Winch:

The portable capstan winch is distinct from other winches because the rope is not kept on a sizable drum attached to the winch. When the winch is in operation, a rope is wrapped around the capstan several times.

The rope is pulled manually to turn the winch, and when it is pulled, it bunches up and rubs against the capstan drum. Consequently, the engine’s pulling power is transferred to the rope, making it simple to winch things.

These winches are portable and can be moved simply onto the job site because they use a small 2 or 4-stroke petrol engine to drive the capstan drum. The PCW3000-Li portable capstan winch is now driven by lithium batteries rather than gasoline, resulting in less noise and no emissions.

They are powerful equipment for their size, and portable capstan winches are available with pulling forces ranging from 400 kg to 1800 kg.

Because they do very little damage and don’t require the construction of rails or other access routes, portable capstan winches are particularly “low impact.” They can be used in delicate, wet, or steep situations.

The rope is used instead of steel cable in capstan winches. The rope is more maneuverable, lighter, and safer than a steel cable. If you need to transport something 200 meters, you can use a 200-meter rope on a capstan winch because the rope can be any length.

Capstan winches are much lighter and easier to carry than drum winches because the rope is not kept on a drum. With a ground speed ranging from 12-42 m/min depending on the model, portable capstan winches are far faster than other winches.

It implies they can work in commercial settings where productivity is vital and remove significant amounts of timber.

Frequently Asked Question:

1. How Did Capstans Work?

To wind a line (rope, cable, or chain) wrapped around it, a capstan consists of a drum that revolves around a vertical axis and is propelled either manually, by steam, or by electricity (see illustration).

2.Is A Capstan A Winch?

An anchoring and mooring device known as a capstan is a small winch employed on a deck or the shore.

The marine capstan is distinguished by its small size, simple design, lightweight, and easy maintenance. It is an economical option for your tiny ships.

3. How Does A Mooring Winch Work?

The main component of a mooring winch assembly is a winch drum with cable or rope coiled around it.

With the aid of a motor drive, the winch drum and warp end are propelled. These components are supported by a strong frame that supports a band brake, clutch, and geared drives.

Conclusion:

The ideal method for moving big objects distant from their intended storage location is to use capstan rope winches. Because there is no length restriction on the rope, you may use any length you like.

A motor, a drum, some power supply, and a rope with the desired length are all you need to make a capstan rope winch.

References: