How Does A Winch Motor Work? – All You Need To Know In 2023

A winch motor is a device that uses the power of a rotating shaft to apply force. It’s most commonly used in industrial applications, such as lifting and moving heavy objects.

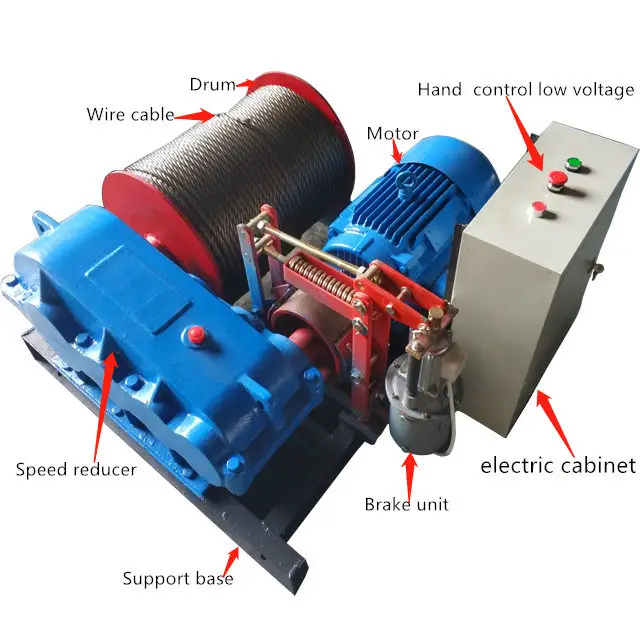

In a winch motor, the rotating shaft is connected to a gearbox. The gearbox sends the power to the rotating armature, which in turn applies force to the rope or chain. This force pulls the object towards the winch motor.

Winch motors provide essential force to rotate the chain or rope around the drum.

It is a rotating shaft with a gearbox connected to it and an armature that applies the force to the chain or rope. The motor provides power to rotate the armature and the chain or rope.

What Is A Winch Motor:

A winch motor is a type of electric motor that is used to lift or move loads. It uses a rotating disk, called a crank, which engages with a helical gear on the winch drum.

The drive system converts rotational motion into linear motion, which can be used to lift or move the load.

The typical winch motor has an output of around 1,000 watts and can lift loads up to 2,000 lbs.

Winch motors are Dc motors or magnetically powered motors.

They are used in a variety of applications, such as construction, agricultural, mining and automotive.

Winch motors are also used in some amusement park rides and for emergency rescues.

There Are Two Main Types Of Winch Motors:

Direct-Drive And Geared-Drive.

Direct-drive motors rely on a single shaft and belt system to transmit power from the engine to the winching armature. Gearing systems can be fixed or variable and provide more flexibility in delivering power. Direct-drive motors are generally cheaper to buy and operate but can be less reliable in extreme conditions.

Geared-drive motors use a set of gears to transmit power from the engine to the winching armature. This system offers excellent reliability and better performance in extreme conditions.

Gears can be changed to adapt to different winching tasks, and they’re usually more expensive to buy than direct-drive motors.

Both types of winch motors use a clutch to engage and disengage the power from the rotating shaft.

This allows them to apply force, even when under pressure, smoothly. A winch motor should be tested periodically to ensure it’s functioning correctly.

Usage Of Winch Motor:

The most common use of a winch motor is to lift heavy objects. It is also used in agricultural applications to pull carts, load animals, and tow vehicles. The winch motor is also used in military applications to pull artillery, vehicles, and other objects.

It can be found in industrial applications such as machine maintenance, manufacturing process automation, mining, construction sites, and more.

Depending on the application, Winch motors are available in various types and sizes. They come with various features such as overload protection, speed control, and thermal protection.

Some motors also have a reverse gearbox for easy attachment to a vehicle’s tow bar. The size of the motor also depends on the application. Some are small and compact, while others are large and require more space.

Winch Motors Types According To Motion:

Winch motor types can be broadly classified into rotary and linear.

Rotary winch motors are typically used for heavier applications where a higher lifting capacity is needed.

These motors have a large diameter shaft and are equipped with a heavy-duty gearbox that provides superior performance.

Linear winch motors are more commonly used for lighter applications requiring higher speed.

These motors have a smaller diameter shaft and a lighter-duty gearbox that provides reduced performance.

Overall, winch motors offer a variety of advantages and disadvantages that should be considered when selecting one for a specific application.

Selecting the correct motor for the job is vital in ensuring maximum performance and efficiency. Winches are an essential part of many industrial applications, so it is crucial to find one that fits the specific needs of your business.

Winch Motors Advantages:

1. Superior lifting capacity:

Winch motors offer superior lifting capacity compared to other motors due to their large diameter shaft and heavy-duty gearbox.

This makes them ideal for applications where a high amount of weight is required to be moved.

2. Reduced speed:

Winch motors typically have a smaller diameter shaft than linear motors, resulting in reduced speeds.

This is beneficial for applications where a fast movement is unnecessary, such as construction sites or forestry operations.

3. Increased safety:

Winch motors have heavy-duty gearboxes that provide increased safety when moving heavy objects.

In addition, the large-diameter shaft ensures that the motor doesn’t contact the lifted object, reducing the risk of injury.

4. Low maintenance:

Winch motors typically have fewer moving parts than other motors, making them less prone to breakdown. They also require less lubrication, making them easier to maintain.

Overall, winch motors offer a variety of advantages and disadvantages that should be considered when selecting one for a specific application.

Selecting the correct motor for the job is essential in ensuring maximum performance and safety.

Winch Motors Drawbacks:

1. Cost:

Winch motors can be expensive compared to other types of motors, depending on the size and features of the unit.

When selecting a winch motor, it is essential to consider factors such as weight capacity, speed, and noise levels.

2. Size:

Winch motors are typically larger than other motors, which can be an obstacle when space is limited.

It is essential to consider the size and dimensions of the object being lifted before selecting a unit.

3. Noise:

Winch motors tend to produce more noise than other motors, which can be disruptive when used in sensitive applications such as construction sites or hospitals. It is essential to consider the noise level of the unit before purchase.

4. Speed:

Winch motors typically have lower speeds than other motors, which can be an obstacle when speed is essential for the application. It is crucial to consider the speed of the unit before purchase.

Conclusion:

Overall, winch motors offer a variety of advantages and disadvantages that should be considered when selecting one for a specific application.

Selecting the correct motor for the job is essential in ensuring maximum performance and safety.

Winch motors are powerful and efficient at the same time as they can control winching with the help of rotating the drum at the rendered winch.

References

Similar Post:

![PTO Winches Vs. Electric Winches: Which To Choose [2023]](https://garagegrabber.com/wp-content/uploads/2022/10/PTO-Winches-Vs.-Electric-Winches-768x402.jpeg)